Over the past five years we’ve had the privilege and honor of working with some of the cycling industry’s finest innovators. There is good reason why we have partnered with the companies that we have. We tend to favor companies that think outside of the box and push the envelope with their technologies. Their products have to be reliable for miles to come and have to perform at an exceptional level. One of these companies is Industry Nine.

Born out of the rocky and rooty terrain of Appalachian country on the Eastern side of the United States. Industry Nine’s signature ‘buzz’ has not so quietly become a fixture in the mountain bike world over the last 13 years. Their Torch hubs have become a go to for those looking for a lightweight, high performance hub that can handle the rigors of even the most unforgiving rider. Industry Nine operates their own machine shop and anodizing facility in Asheville, North Carolina. This allows them to offer a plethora of colour options, and hub configurations for virtually every standard under the sun. We have built with Industry Nine’s light and reliable Torch hub for the last 5 years with great feedback from our athletes and customers. Today we’re going to take a look into some of the technology that makes this hub unique.

Engagement.

Quick engagement is absolutely essential in mountain biking. Technical terrain with varying levels of traction mean that the rider must constantly be adjusting their power output to prevent from spinning out or stalling. Having control of this power comes down to how effectively the drivetrain can transmit this pedal force to the wheels. This is where Industry Nine’s torch hub shines.

| Hub Brand | Engagement Points | Degree rotation to Engage |

| Onyx Racing Products | Infinite | <1 degree |

| Project 321 | 216 | 1.67 |

| Industry 9 | 120 | 3 |

| Chris King | 72 | 5 |

| Hope Pro 4 | 44 | 8.2 |

| Shimano | 36 | 10 |

| DT Swiss (Stock) | 18 | 20 |

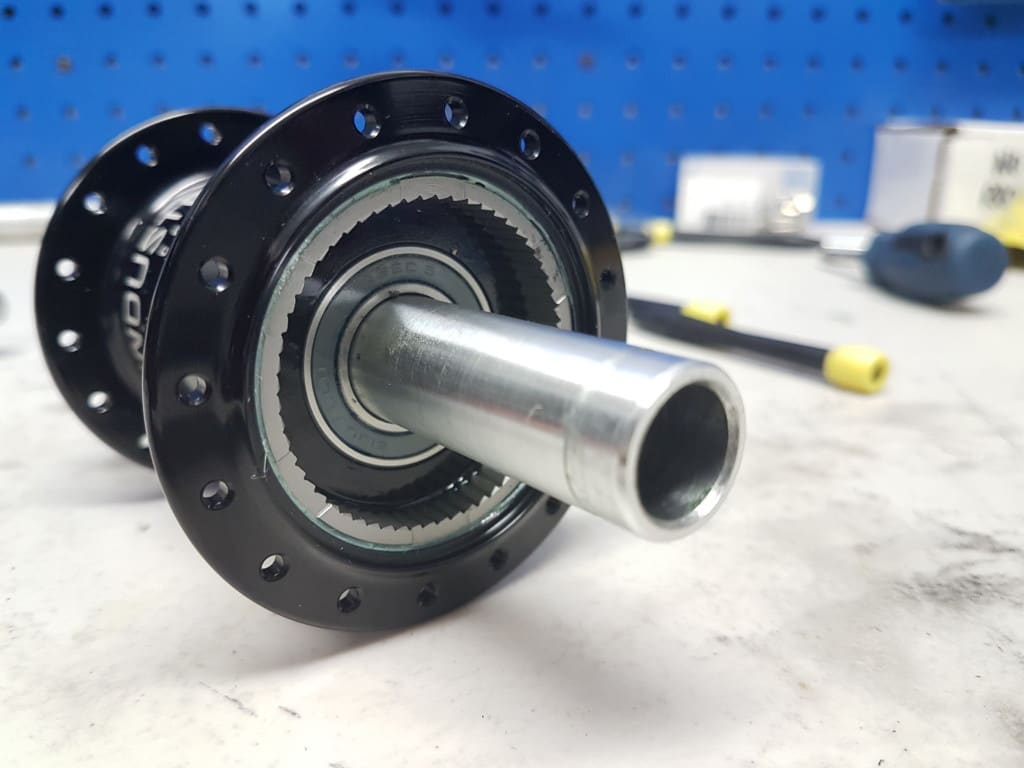

The 60 tooth hardened steel drive ring is the heart of the Torch’s quick and reliable engagement. 3 pawls engage with this ring at a time.

Using a combination of 7075 Aluminum, hardened steel on the drive components and clever machining, the Torch hub comes in at a very competitive weight, about 440g for a front and rear set of boost 6bolt hubs. For this reason, many of our weight conscious customers often opt for Industry Nine hubs for their builds. A set of our 27.5 TR33 laced to Industry Nine hubs with CX ray spokes comes in at 1490g! Not bad for a hard charging enduro wheelset!

As mentioned previously, we only partner with brands that create products that are time proven and dependable. Industry Nine makes no exception to this. Their hubs have been incredibly reliable in our experience and have stood the test of time in our rainy, unforgiving Pacific Northwest climate. In the event that something does wear out or requires servicing, the process is simple and parts are readily available. This means minimal downtime and more time on the trail!

Last but not least Industry 9’s in house Ano Lab means they offer a full spectrum of colour options. Perfect to match or contrast your ride. Our customers have taken full advantage of this to customize their whips.