Treat your Bike

After a long season of riding, we always encourage customers to do a full inspection of their wheels to address any potential concerns, and ensure they’ll be ready to roll at full speed next season.

Moving parts such as bearings and freehubs are prone to wear and tear, and spokes and nipples have a fatigue life when ridden hard. Taking the time to inspect each component and performing the necessary maintenance will keep your wheels running Fast & True for years to come!

Check for Trueness

When you check for trueness, you’re essentially checking to see if the wheel is running straight. Big impacts, g-outs and rough terrain can be super hard on wheels over time, and on occasion the right impact can put your wheel out of true and cause a wobble. Generally, a side to side wobble less than 2.5mm is no reason for immediate concern but anything larger than that should be addressed as soon as possible.

If your wheel requires truing, you have a few options. If your local bike shop has a reputable wheel builder on staff, they can likely help you out. But, we do recommend that they contact us for the correct spoke tension specs if they’re unsure. You’re also welcome to send your wheels to us for a tune-up, as we happily offer a lifetime of truing and wheel service for the original owner!

Check Your Spoke Tension

The spokes and nipples of your wheelset are subject to an extreme level of load. Every impact from rocks, roots and bumps on the trail are absorbed and transferred through the spokes and nipples. Heavy impacts, drops and jumps also place an immense burden on the spokes. Depending on the amount and intensity of your riding, spokes will fatigue over time. This generally shouldn’t occur until after a few seasons of decent use but it’s a good idea to check your spoke tension each year.

Measurements should be taken with a proper tensiometer (most bike shops have this tool) and with the tire removed, as an inflated tire will affect tension measurements. Again, we encourage you to send your wheels back to us to have them serviced and trued if possible.

All NOBL wheel sets are built to a maximum tension range of 120-130kgf. The tension should be close to this range and consistent across all spokes, with the rear drive side having slightly higher tension. If there is a significant variance from this accepted range, it’s typically worthwhile to have the wheel tensioned and trued.

Inspect Your Hub

Your wheels will only spin as well as the hub allows, which is why it’s essential to make sure your hub is operating at maximum efficiency during wheel care. Hubs are intricate components with an engagement mechanism, seals and several bearings. Each of these components are subject to high loads and plenty of wear and tear from being exposed to the elements. Regular inspection of these components and some basic maintenance such as cleaning and replacing the old grease with clean grease will add years to the lifespan of your hub.

Hub service should be executed by an authorized dealer. If you’re able to send your wheels back to us, we can perform a comprehensive service when we true the wheels.

If you’re stoked to perform the maintenance on your own, this is what you should look for with each hub model:

Industry Nine

A cleaning and fresh injection of grease in your Hydra, Torch or 101 will breathe new life into the hub, be sure to use Industry Nine’s specified Dumonde tech oil or grease.

Inspect the bearings to see if they have become rough or gritty. If they feel rough or notchy, we highly recommend replacing them as soon as you have some down time. Depending on where you’re located, you should be able to order a bearing kit through i9, and we also keep a healthy stock of replacement parts at all times.

As a note, you will need the special tools to remove and install new bearings on any of your hubs if you’re doing the service on your own.

Chris King

The Chris King hub will provide years and years of reliable service as long as a maintenance schedule is followed. At the very least, an annual inspection of the ring drive mechanism should be done to ensure everything is on track.

Both dirt and gradual wear and tear on the ring drive will cause the grease to turn black and lose its lubricity properties. A good cleaning plus some fresh grease will make your Chris King hub spin as good as new!

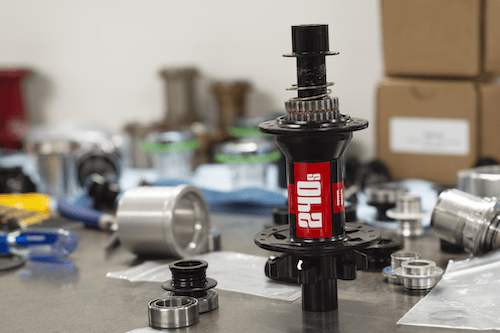

DT Swiss

While incredibly reliable and generally maintenance-free, a cleaning and fresh grease goes a long way to ensuring that DT’s Star Ratchet and Ratchet EXP hubs continue to spin freely and engage reliably. Just be sure to only use DT’s specific Star Ratchet/EXP grease, and to use it sparingly.

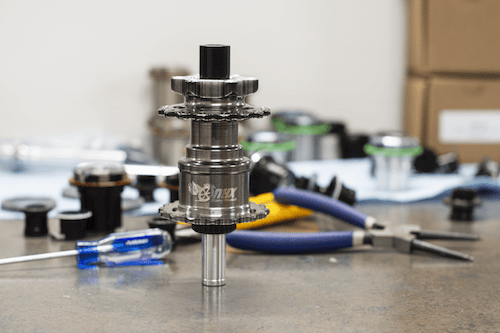

Onyx

Onyx Classic and Vesper hubs require very little maintenance. As long as the hub is spinning easily, there is a good chance you can leave it as is during wheel care. Should they feel rough, Onyx has a detailed set of videos on how to service their hubs.

Bearings that feel rough or notchy should be replaced and we keep stock of both regular and ceramic bearings in stock at our warehouse.

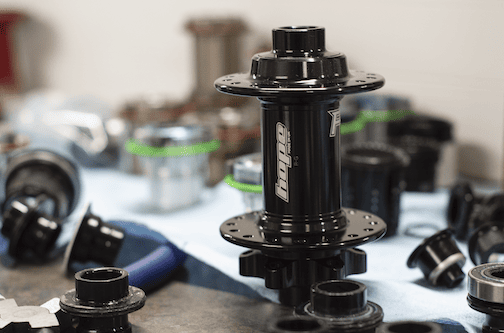

Hope

Hope’s simple, tried and true leaf spring pawl system is reliable and easy to service. An annual clean and re-grease will keep both Pro 4 and Pro 5 hubs spinning for years. A medium waterproof grease is recommended for this application.

As always, we recommend checking your bearings and replacing them if necessary at the end of the season.

A little love for your wheels goes a long way

We’ve designed our wheels to be ridden for years and to move from bike to bike with you. Taking these simple and preventative maintenance steps will prolong the life of your wheel set, as well as guarantee you catch any potential problems early.

If you have more questions or need assistance with service, we encourage you to reach out to our customer support team and someone will be in touch!